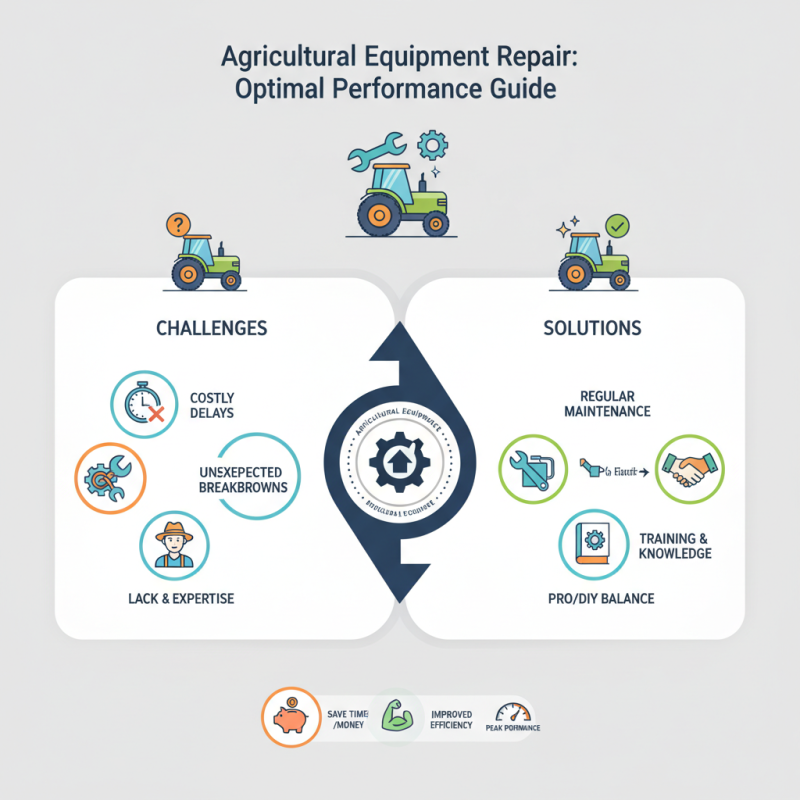

Agricultural equipment repair is crucial for maintaining farm productivity and efficiency. When machinery fails, the delays can be costly. Farmers often face unexpected breakdowns that interrupt vital tasks. Regular maintenance can prevent many of these issues. However, not all farmers have extensive repair knowledge.

Troubleshooting can feel overwhelming. Common mechanical problems may go unnoticed until they escalate. A small issue can lead to significant equipment failures. This reality highlights the importance of training and awareness. Learning the basics of agricultural equipment repair is beneficial.

Investing in repair skills can save time and money. However, relying solely on DIY methods can be risky. Professional repair services offer expertise that many farmers lack. Striking a balance between self-repair and professional help is essential. Effective agricultural equipment repair practices ensure that machinery operates at peak performance.

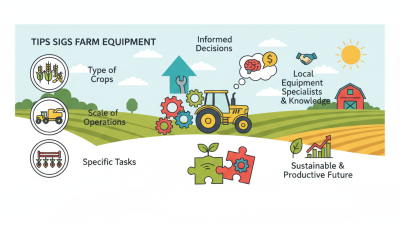

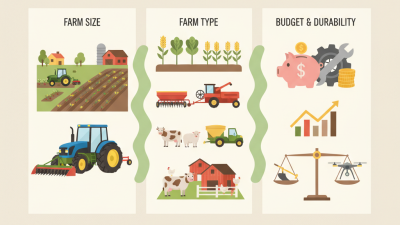

Agricultural equipment plays a crucial role in modern farming. Tractors, plows, and harvesters are commonly used tools. Each type of equipment has unique maintenance needs. For instance, tractors require regular oil changes and tire checks. Plows need frequent blade sharpening for effective soil cultivation. Neglecting these tasks can lead to decreased efficiency and higher repair costs.

In addition, proper cleaning is vital for all equipment. Dirt and debris can cause wear and tear. A simple wash after each use can extend the life of your machinery. Check belts and hoses regularly for cracks or fraying. These issues can sneak up if not monitored closely. Farmers often overlook minor details, leading to costly breakdowns.

The importance of operator training cannot be stressed enough. Even well-maintained equipment can malfunction if not used correctly. Understanding each machine’s limits can prevent accidents and reduce wear. Many farmers face challenges in balancing maintenance with daily tasks. This tension can lead to overlooked equipment needs, affecting performance and productivity.

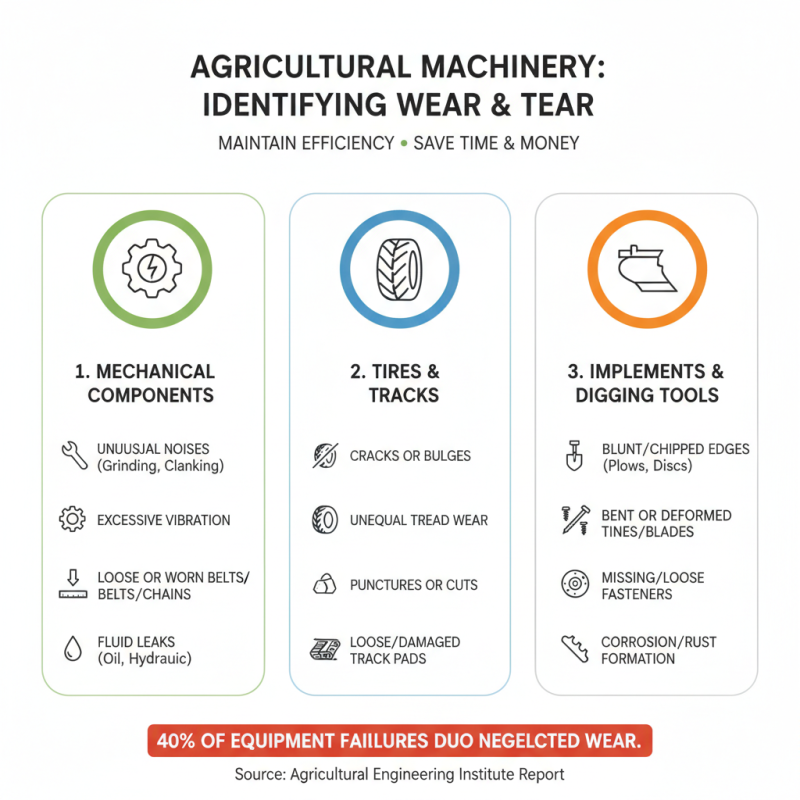

Identifying signs of wear and tear in agricultural machinery is crucial for maintaining efficiency. According to a recent report by the Agricultural Engineering Institute, nearly 40% of equipment failures are linked to neglected wear. Recognizing early signs can save both time and money in repairs.

Common indicators include unusual noises, diminished performance, and visible damage. Check for cracks in the frames or excessive rust. Worn-out belts and frayed cables can lead to bigger issues if overlooked. Keep an ear out for grinding sounds or vibrations. These can indicate internal problems that need immediate attention.

**Tips:** Regularly inspect machinery before use. A monthly check can prevent severe damage. Monitor oil levels and replace filters as recommended. Simple maintenance tasks can extend the lifespan of your equipment. Don't wait for breakdowns. Proactive measures are essential for optimal performance. Make note of any minor issues. They are often telling signs of greater underlying problems that could affect efficiency.

Troubleshooting agricultural equipment can be challenging. Many farmers rely on their machines for daily operations. Industry data indicates that around 30% of machinery failures occur due to maintenance neglect. Regular inspections can help prevent major breakdowns.

Start by identifying any unusual noises or vibrations. These can indicate underlying issues. Check fluid levels regularly. Low oil pressure might lead to engine damage. Always refer to the operator's manual for specific troubleshooting advice.

**Tip:** Keeping a log of maintenance activities can show trends over time.

Next, examine hydraulic systems. Leaks can cause loss of performance. Inspect hoses for wear or damage. A small crack can lead to larger, costly repairs. Collector reports show that addressing hydraulic issues early can increase efficiency by 20%.

**Tip:** Create a checklist for routine inspections to ensure nothing is overlooked.

Finally, test electronic components to ensure they are functioning. Faulty sensors can produce inaccurate readings. This can affect your equipment’s performance. Familiarize yourself with common error codes to save time during repairs. Preventive maintenance can extend equipment life. Don't ignore minor problems; they can escalate quickly.

When it comes to repairing agricultural equipment, having the right tools is essential. Basic tools like wrenches, screwdrivers, and pliers are crucial. But you might also need specialized equipment like torque wrenches or hydraulic jacks. Don't forget personal protective gear, such as gloves and goggles, to ensure safety during repairs.

Tips: Always check your tools before starting a repair. A missing tool can delay the job. Keep the workspace clean and organized. It reduces the risk of accidents and makes the process smoother.

Techniques also matter in effective repairs. Begin by diagnosing the issue thoroughly. Isolate the problem for a more manageable fix. Take your time during disassembly to avoid damaging components. Document each step. Sometimes, you may find that parts are more worn out than expected. This can lead to the need for replacements, which requires careful planning.

Tips: While working, maintain a focused mindset. Avoid multitasking, as it increases the chance of mistakes. After repairs, do a test run. This helps ensure everything runs smoothly. Learning from past failures can lead to better techniques in the future. Embrace those lessons for continuous improvement.

Regular maintenance of agricultural equipment is crucial for optimal performance. A thorough inspection should be part of every maintenance routine. Check for leaks, wear, and loose components.

Small issues can lead to major breakdowns. For instance, a slight crack in a hose can result in significant downtime. It's essential to address these problems before they escalate.

Cleaning equipment is another important task. Dust and debris can hinder performance and cause damage. After every use, make it a habit to clean the machinery. Pay special attention to filters.

Clogged filters reduce efficiency and increase fuel consumption. Noticing these details can have a big impact.

Additionally, operators should keep a maintenance log. Documenting when and what was serviced helps track patterns. This could reveal recurring issues that need attention. Sometimes, minor repairs are overlooked.

Take time to reflect on what could be improved. Maintenance is not just a checklist; it's an ongoing process. Prioritizing these practices enhances the lifespan of equipment.